Product Overview

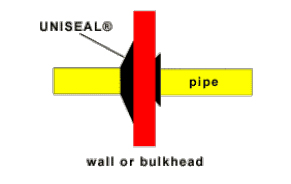

Uniseal® is simply the world’s best seal and installing the Uniseal® is a simple process. After cutting a hole in the wall of a tank or other surface, the seal is inserted. Then the pipe is coated with a slippery detergent and pushed into the seal. The Du Pont Alcryn® is the key to the liquid-tight seal. When the pipe is pushed through the rubber-like Uniseal® from the outside, the inside Alcryn® wall becomes thin enough to allow the pipe to squeeze through and then forms a liquid-tight seal. The coefficient of friction with the plastic pipe is roughly three times higher than any other material which allows it to create a better seal than with any other material. In static conditions the seal is good up to 65 PSI. Uniseal® can withstand pressure, and suction, acids, oils, greases, gasoline, sewage, waste, heat and cold. It offers long life, easy installation and reduced labor and material costs.

Hole sizing:

3" (U300) = 4" Hole Saw

4" (U400) = 5" Hole Saw

Instructions For Using UNISEAL®

1. Cut hole to the Holesaw size indicated for the UNISEAL® you are using

Example 3" UNISEAL® = 4" Hole (Holesaw)

2. Ensure the hole is clean cut with sharp edges. Irregularities could cause poor seating and ultimate leakage.

3. Insert UNISEAL® into hole with the wideside facing the pipe to be inserted.

4. Make certain that the pipe end to be inserted is clean cut. File the edges so that there are no sharp points to cut the UNISEAL®

5. Using Detergent, lubricate the outside of the pipe end to be inserted, then push the pipe through the UNISEAL® from the large flange side. The detergent will be squeezed off as the pipe passes through the UNISEAL® The co-efficient of friction of the rubber holds the pipe tightly in place.